Jasca

BREAD & PASTRIES

How consistent is your dough quality?

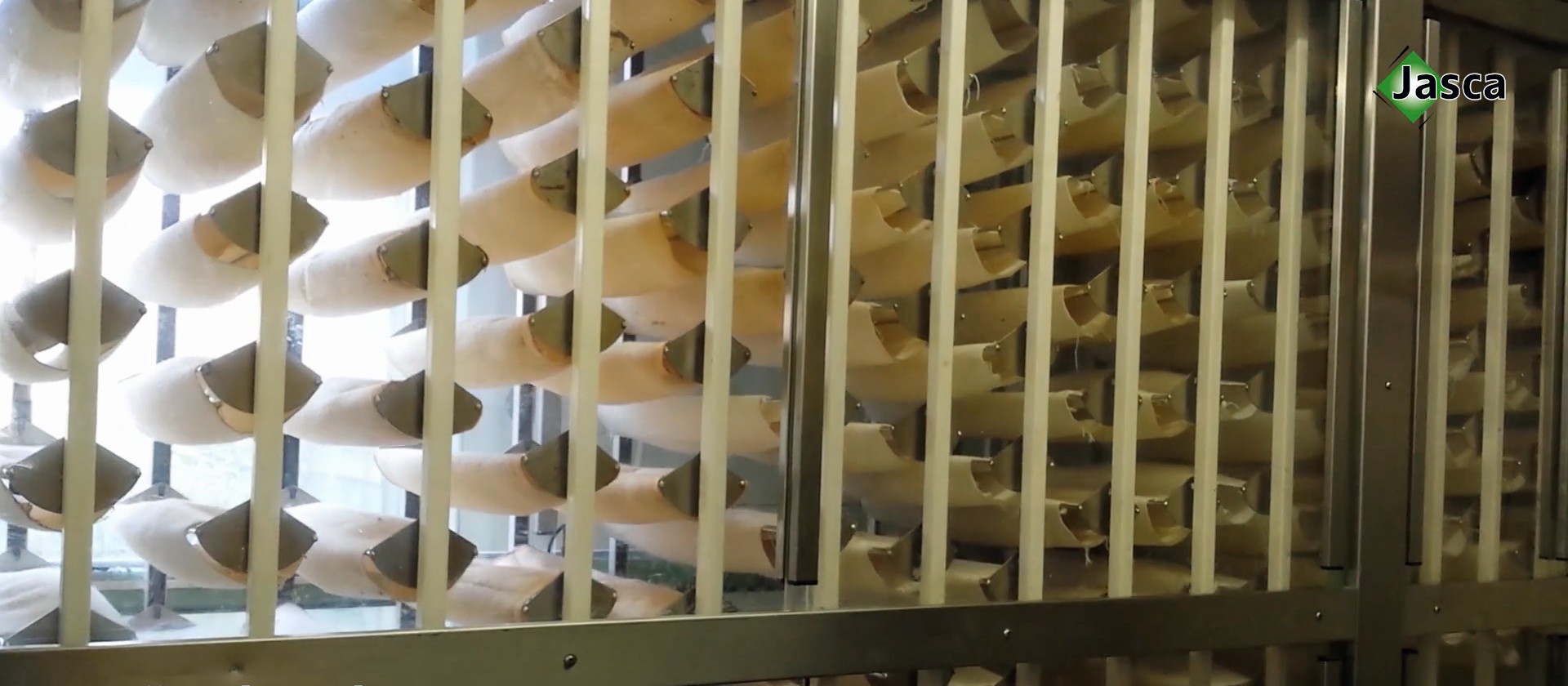

Jasca’s unique, customised air fogging system reduces dehydration in your dough products, ensuring consistent quality. It evenly distributes heat and maintains stable humidity levels. Dough is delicate and highly susceptible to dehydration during processes such as proofing. Often, while ambient temperatures within proofing cabinets or rooms might be adequately warm, humidity levels can fall short, or the dough might cool during the process. Such disparities lead to varying rates of rise between the dough's core and surface, resulting in irregular crumb structures. Therefore optimising your bakery processes with precise humidity and temperature control ensures constant dough quality.

Various application possibilities

Beyond atomising in proofing and cooling spaces, our atomisation system is applicable to bowl and kneader atomisation, featuring patented atomisers for periodic self-cleaning. Jasca’s atomisation systems find use in the bakery sector for tasks such as bulb cabinets, post-proofing cabinets, points cabinets, process rooms (room and workstation atomisation), belt atomisation, hoppers, tubs, kneaders, cooling towers, alcohol atomisation in bread bags for extended shelf life, pre- and post-oven applications, and disinfection.